BMM Series Orbital Hydraulic Motor

Key words:

Classification:

Description

The BMM series orbital hydraulic motor is a miniature shaft distribution motor that can be installed and used in a small space. It adopts insert column type rotary stator pair, 4/5 tooth structure, compact structure, light weight and high power density. Its characteristics:

• The use of advanced stator parameters design, low starting pressure, high efficiency, and good retention, smooth operation.

• High shaft seal pressure, can be used in series and parallel.

• Advanced structure design, high power density.

Main technical parameters

|

Type |

BMM 8 |

BMM 12.5 |

BMM 20 |

BMM 32 |

BMM 40 |

BMM 50 |

|

|

Actual displacement (cm³/rev.) |

8.2 |

12.9 |

20.4 |

32.7 |

40.9 |

51.1 |

|

|

Maximum speed (rpm) |

Rated |

1537 |

1256 |

794 |

495 |

440 |

352 |

|

Continuous |

1950 |

1550 |

931 |

581 |

465 |

372 |

|

|

intermittent |

2450 |

1940 |

1220 |

757 |

606 |

484 |

|

|

Maximum torque (N.m) |

Rated |

8 |

13 |

20 |

32 |

38 |

43 |

|

Continuous |

11 |

16 |

25.6 |

41 |

46 |

58 |

|

|

intermittent |

15 |

23 |

36 |

59 |

72 |

91 |

|

|

Peak |

21 |

33 |

52 |

66 |

84 |

104 |

|

|

Maximum output power (KW) |

Rated |

1.3 |

1.7 |

1.7 |

1.7 |

1.7 |

1.2 |

|

Continuous |

1.8 |

2.4 |

2.4 |

2.4 |

2.2 |

1.8 |

|

|

intermittent |

2.6 |

3.2 |

3.2 |

3.2 |

3.2 |

3.2 |

|

|

Maximum working pressure difference (MPa) |

Rated |

9 |

9 |

9 |

9 |

8.5 |

7.5 |

|

Continuous |

10 |

10 |

10 |

10 |

9 |

9 |

|

|

intermittent |

14 |

14 |

14 |

14 |

14 |

14 |

|

|

Peak |

20 |

20 |

20 |

16 |

16 |

16 |

|

|

Maximum flow (L/min) |

Rated |

14 |

18 |

18 |

18 |

20 |

20 |

|

Continuous |

16 |

20 |

20 |

20 |

20 |

20 |

|

|

intermittent |

20 |

25 |

25 |

25 |

25 |

25 |

|

|

Type |

Maximum oil inlet pressure |

|

|

BMM8-50 (MPa) |

Rated |

9 |

|

Continuous |

10 |

|

|

intermittent |

14 |

|

* The rated speed and torque refer to the output value under the rated flow and pressure.

* Continuous value refers to the maximum value that the displacement motor can work continuously.

* The intermittent value refers to the maximum value of the displacement motor working for 6 seconds in 1 minute.

* The peak value refers to the maximum value of the displacement motor working for 0.6 seconds in 1 minute.

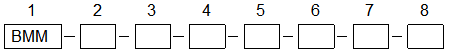

Ordering Information

|

POS.1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

||||||

|

Structure Code |

Displacement |

Flange, stop |

shaft extension |

Oil outlet and outlet |

rotating condition |

Paint Options |

Special features |

||||||

|

BMM |

8 |

M |

3-M6 round flange, stop φ31.5X5 |

A |

Straight axis φ16, flat key 5x 5x 16, length 28.5,M6 |

E |

G3/8,G1/8 |

None |

Standard |

00 |

No paint |

|

|

|

12.5 |

U |

3-1/4-28UNF round flange, stop φ31.5X5 |

B |

Straight axis φ15.875, flat key 4.8x 4.8x 19.05, length 28.5,1/4-28UNF |

U |

9/16-18UNF 'O'-ring,3/8-24UNF 'O'-ring |

R |

Reverse |

None |

blue paint |

None |

General |

|

|

20 |

F |

2-φ9 rhombic flange, stop φ63X2 |

C |

Involute spline shaft φ16.5,B17X14(DIN5482), length 28.5,M6 |

1E |

Rear port G3/8,G1/8 |

|

|

B |

Black paint |

|

|

|

|

32 |

|

|

|

|

1U |

Rear port 9/16-18UNF 'O'-ring,3/8-24UNF 'O'-ring |

|

|

S |

silver gray paint |

|

|

|

|

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: When using the ordering information, the user can write the motor structure, displacement, mounting flange, shaft extension, oil inlet and outlet and other information to us according to the above format by selecting the code of the colored part on the left. If the selected specifications are not in the above table or special requirements, please contact us.

Factory

Previous:

The next one:

Inquiry