BMT Series Orbital Hydraulic Motor

Key words:

Classification:

Description

BMT series orbital hydraulic motor is an advanced hydraulic motor with end-face flow distribution structure. This series of motors use a column-mounted rotating stator pair, which has the characteristics of high working pressure, high working efficiency, good efficiency retention of the whole machine and long working life. On the basis of standard structure, multi-functional variant design can be carried out according to user requirements. Its characteristics:

• The use of advanced stator parameter design, low starting pressure, high efficiency and good retention.

• High working pressure and large output torque. Tapered roller bearing structure, bearing shaft, radial load capacity is strong, so that the motor can directly drive the working mechanism, the scope of use is expanded.

• Advanced end face flow distribution structure, so that the motor with high precision, wear after the automatic compensation function is strong, to ensure high volumetric efficiency, motor long life, to ensure that the motor speed is stable, smooth load speed characteristics.

Main technical parameters

|

Type |

BMT BMTZ 160 |

BMT BMTZ 200 |

BMT BMTZ 230 |

BMT BMTZ 250 |

BMT BMTZ 315 |

BMT BMTZ 400 |

BMT BMTZ 500 |

BMT BMTZ 630 |

BMT BMTZ 800 |

|

|

Actual displacement (cm³/rev.) |

166.6 |

210 |

234.5 |

267.9 |

337 |

426.7 |

535.8 |

672.1 |

853.1 |

|

|

Maximum speed (rpm) |

Rated |

455 |

455 |

410 |

358 |

285 |

220 |

180 |

140 |

110 |

|

Continuous |

590 |

580 |

520 |

460 |

365 |

290 |

230 |

182 |

143 |

|

|

intermittent |

740 |

710 |

630 |

555 |

440 |

350 |

280 |

220 |

175 |

|

|

Maximum torque (N.M) |

Rated |

390 |

490 |

535 |

619 |

780 |

930 |

1080 |

1170 |

1280 |

|

Continuous |

485 |

613 |

675 |

770 |

980 |

1120 |

1245 |

1400 |

1550 |

|

|

intermittent |

580 |

735 |

825 |

935 |

1170 |

1300 |

1400 |

1600 |

1600 |

|

|

Peak |

690 |

870 |

965 |

1100 |

1385 |

1500 |

1680 |

1800 |

1800 |

|

|

Maximum output power (KW) |

Rated |

18.7 |

23.4 |

23.2 |

23.2 |

23.3 |

21.4 |

20.4 |

18.2 |

15.3 |

|

Continuous |

27.7 |

34.9 |

34.7 |

34.5 |

34.9 |

31.2 |

28.8 |

25.3 |

22.2 |

|

|

intermittent |

32 |

40 |

40 |

40 |

40 |

35 |

35 |

27.5 |

26.8 |

|

|

Maximum working pressure difference (MPa) |

Rated |

16 |

16 |

16 |

16 |

16 |

15 |

14 |

12 |

10.5 |

|

Continuous |

20 |

20 |

20 |

20 |

20 |

18 |

16 |

12 |

10.5 |

|

|

intermittent |

24 |

24 |

24 |

24 |

24 |

21 |

18 |

16 |

13 |

|

|

Peak |

28 |

28 |

28 |

28 |

28 |

24 |

21 |

19 |

16 |

|

|

Maximum flow (L/min) |

Rated |

80 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

Continuous |

100 |

125 |

125 |

125 |

125 |

125 |

125 |

125 |

125 |

|

|

intermittent |

125 |

150 |

150 |

150 |

150 |

150 |

150 |

150 |

150 |

|

|

Maximum allowable oil inlet pressure (MPa) |

Rated |

21 |

21 |

21 |

21 |

21 |

21 |

21 |

21 |

21 |

|

Continuous |

21 |

21 |

21 |

21 |

21 |

21 |

21 |

21 |

21 |

|

|

intermittent |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

|

Peak |

30 |

30 |

30 |

30 |

30 |

30 |

30 |

30 |

30 |

|

* The rated speed and torque refer to the output value under the rated flow and pressure.

* Continuous value refers to the maximum value that the displacement motor can work continuously.

* The intermittent value refers to the maximum value of the displacement motor working for 6 seconds in 1 minute.

* The peak value refers to the maximum value of the displacement motor working for 0.6 seconds in 1 minute.

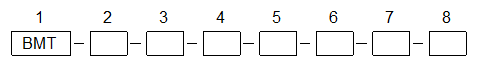

Ordering Information

|

POS.1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

||||||

|

Structure Code |

Displacement |

Flange, stop |

shaft extension |

Oil outlet and outlet |

rotating condition |

Paint Options |

Special Function |

||||||

|

BMT |

160 |

4 |

4-φ14 square flange, φ160, stop φ125X9 |

M |

Straight axis φ40, length 82, flat key 12X8X70,M12 |

D |

G3/4,G1/4, plate type 4-M10 |

None |

Standard |

00 |

No paint |

None |

General |

|

200 |

K6 |

4-φ14.5 square flange, φ162, stop φ127X9 |

FD |

Involute spline shaft φ38.1, length 82,17-DP12/24,M12 |

M |

M27X2,M14X1.5, PLATE 4-M10 |

R |

Reverse |

None |

blue paint |

|

|

|

|

230 |

|

|

FE |

Involute spline shaft φ38.1, length 57,17-DP12/24,3/8-16UNC |

S |

1-1/16-12UN 'O'-ring,9/16-18UNF 'O'-ring |

|

|

B |

Black paint |

|

|

|

|

250 |

|

|

FG |

Involute spline shaft φ38.1, length 114,17-DP12/24, shaft head φ25X26.7 |

S1 |

1-1/16-12UN 'O'-ring,7/16-20UNF 'O'-ring |

|

|

S |

silver gray paint |

|

|

|

|

315 |

|

|

SL |

Rectangular spline shaft 6-34.85X28.14X8.64, long 102,M8 |

G |

G3/4,G1/4 |

|

|

|

|

|

|

|

|

400 |

|

|

G |

Straight axis φ38.1, length 82, flat key 9.525X9.525X57.15,3/8-16UNC |

M3 |

M27X2,M14X1.5 |

|

|

|

|

|

|

|

|

500 |

|

|

G1 |

Straight axis φ31.75, length 57, flat key 7.96X7.96X40,3/8-16UNC |

|

|

|

|

|

|

|

|

|

|

630 |

|

|

J |

Rectangular spline shaft 6-30X24.8X6, long 46.2,M8 |

|

|

|

|

|

|

|

|

|

|

800 |

|

|

T |

φ45 cone shaft, taper 1:10, cone length 54, flat key 12*8*28, shaft head length 82, shaft end thread M30X2 |

|

|

|

|

|

|

|

|

|

|

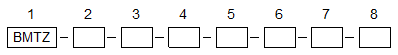

POS.1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

||||||

|

Structure Code |

Displacement |

Flange, stop |

shaft extension |

Oil outlet and outlet |

rotating condition |

Paint Options |

Special features |

||||||

|

BMTZ |

160 |

Z2 |

2-φ14 rhombic flange, φ140, stop φ100X9 |

B |

Straight shaft φ32, length 56, flat key 10X8X45, shaft head thread M8 |

ZD |

G3/4,G1/4, plate type 4-M10 |

None |

Standard |

00 |

No paint |

None |

General |

|

200 |

Z4 |

4-φ13 square flange, φ160, stop φ125X8 |

Y |

Straight axis φ40, length 65, flat key 12X8X45,M12 |

ZM |

M27X2,M14X1.5, PLATE 4-M10 |

R |

Reverse |

None |

blue paint |

|

|

|

|

230 |

B2 |

4-φ13 square flange (120X120), thread pitch 90X90, stop φ100X6 |

B1 |

Straight shaft φ32, length 60, flat key 10X8X45, shaft head thread M12 |

ZS |

1-1/16-12UN 'O'-ring,9/16-18UNF 'O'-ring |

|

|

B |

Black paint |

|

|

|

|

250 |

|

|

G |

Straight axis Φ 38.1, length 82, flat key 9.525X9.525*57.15,3/8-16UNC |

ZS1 |

1-1/16-12UN 'O'-ring,7/16-20UNF 'O'-ring |

|

|

S |

silver gray paint |

|

|

|

|

315 |

|

|

|

|

ZG3 |

G3/4,M10X1 |

|

|

|

|

|

|

|

|

400 |

|

|

ZM4 |

M27X2,M10X1 |

|

|

|

|

|

|

|||

|

500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

630 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

800 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: When using the ordering information, the user can write the motor structure, displacement, mounting flange, shaft extension, oil inlet and outlet and other information to us according to the above format by selecting the code of the colored part on the left. If the selected specifications are not in the above table or special requirements, please contact us.

Factory

Previous:

The next one:

Inquiry